This post was originally published on Healthy Forest

Editors note: Kyle Johnson is a forester with the Bureau of Land Management’s Missoula Field Office. Mr. Johnson is not affiliated with Healthy Forests, Healthy Communities but gave us permission to share his message.

It seems like the topic everyone is talking about these days: the closures of Pyramid Mountain Lumber in Seeley Lake, MT, and Roseburg Forest Products particle board plant in Missoula. From the office break room, to presenting a guest lecture at the University, to my neighbors talking the street – everyone wants to know: How will these mills closing effect us? My short answer is: How will they not effect us? That answer is a little snippy but not wrong. The truth is the closures will have direct effects and indirect effects, like dropping a pebble in a pond. The immediate splash catches your attention, but the ripples last much longer and reach much further.

This week I had the chance to visit a timber sale area that we offered several years ago near Potomac, MT. The project was primarily a Ponderosa Pine thinning, where we reduced the stocking of the stand to improve forest health and resiliency, reduce hazardous fuels and risk of catastrophic wildfire near homes, and produced just about a million board feet of timber which went to Pyramid Mountain Lumber (the resulting sawdust from milling likely went to Roseburg). The footprint of the sale area was just under 400 acres, and all that work was done while still returning around $80,000 to our healthy forests fund (which gets spent on planting, young tree thinning and the like).

As I walked through the area and listened to our fuels staff make plans to implement a broadcast burn on the site, I was struck by the thought that this timber sale likely wouldn’t happen today. The main reason for that is that Pyramid was the last sawmill in our area that would take Ponderosa Pine (a species which takes longer to dry and has more limited utility than Douglas-fir or Western larch). So, if we offered that sale again today there is a real possibility that we’d have to make it a stewardship contract and offset the cost of hauling logs to a mill farther away with agency funds. Rather than a timber sale with a positive return, this project would cost money and reduce our ability to accomplish other work. That’s what I mean by direct and immediate effects of the mill closures.

The indirect effects will take a little longer to feel, but they will be just as if not more impactful. Many of our goals and objectives at the Missoula Field Office are tied to forest restoration, fuels reduction, habitat improvement and the like. All of those are active management programs where real acres are getting treated. That means real operators with real tractors getting the work done to our specifications.

The point here is that while we government types do a lot of planning, and writing and talking about good projects, we don’t actually do the work. That is the marriage between the public and private sectors and our ability to implement projects depends on a robust pool of skilled operators. When we offer a contract for bid, be that for a fish habitat improvement, road blading, timber harvest or anything else, we need quality operators to bid on them and get the work done- otherwise we’ve accomplished nothing. In a nutshell, we can’t do our job without the operators. When a mill closes, those operator’s ability to survive and make a living is diminished, and pretty soon we don’t have contractors to bid on our projects. Those are the ripple effects that may take years to play out.

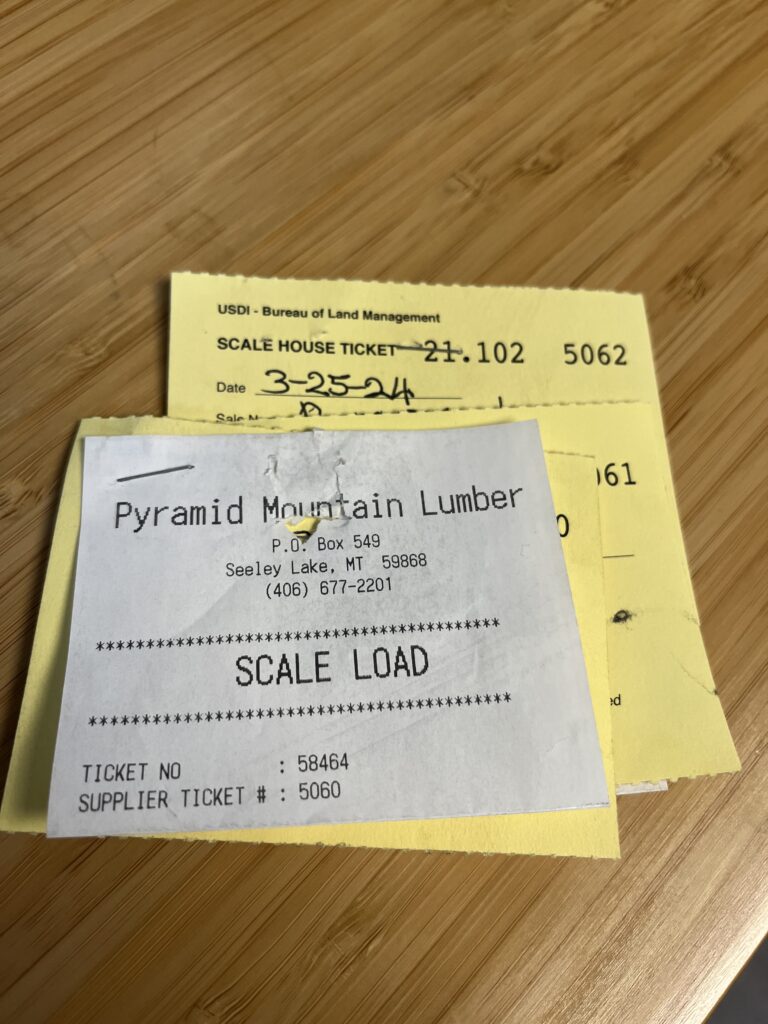

This week I received our last log load slips from Pyramid Mountain Lumber, a mill that has been in operation for 75 years, and certainly a mainstay for my whole career. And while this makes me sad and reflective, it’s not my job that was lost. My heart goes out to those folks who’ve lost their jobs and all their families. That’s the real tragedy.

Source: Healthy Forest

0 Comments