This post was originally published on Sustainability Matters

UNSW Sydney researchers have made an important breakthrough that could transform photovoltaic technology, making solar cells more environmentally friendly, cost-effective and efficient.

The scientists, from UNSW’s School of Photovoltaic and Renewable Energy Engineering, managed to achieve a best-ever efficiency of 13.2% for high bandgap kesterite solar cells.

While kesterite is a naturally occurring mineral, it can also be artificially created at low cost by combining copper, zinc, tin and sulfur — all abundant, non-toxic materials. Taking its name from these component parts, synthesised kesterite is known as CZTS.

CZTS is a promising material for future generations of solar cells because it is environmentally friendly, relatively inexpensive to manufacture and known to maintain its photovoltaic performance over a long period of time. However, it hasn’t been widely adopted at this stage because it is subject to defects during production, hampering its efficiency.

Led by Scientia Professor Xiaojing Hao, the UNSW team has helped to solve this problem by annealing, or heat-treating, the CZTS solar cell device in a hydrogen-containing atmosphere. The fundamental research behind the record-breaking efficiencies, which first achieved 11.4% after six years of stagnation for CZTS, has now been published in the journal Nature Energy.

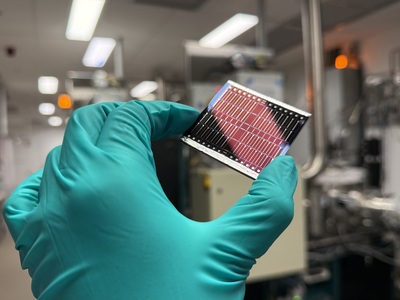

The record-breaking kesterite solar cell developed at UNSW. Photo: UNSW Sydney.

“The big picture here is that we ultimately want to make electricity cheaper and greener to generate,” Hao said.

“Silicon modules have almost reached the limit of their theoretical efficiency, so what we are trying to do is answer the question coming from the PV industry as to what the next generation of cells will be made of.

“And as well as that, how can we make solar panels less expensive to manufacture, and how can we get more electricity per area so the panels can be particularly beneficial for area-limited PV applications?”

Passivating effect of hydrogen

Before the team’s breakthrough, the maximum photovoltaic efficiency of CZTS had been stuck at 11% for the past six years. Now, they expect their use of hydrogen during production to advance CZTS’s efficiency even further.

“In basic terms, to create CZTS you take copper, tin, zinc and sulfur and ‘cook’ them all together at a certain temperature which turns it into a material you can use as a semiconductor,” Hao said.

“The tricky part is controlling the defects that are introduced during that process. What we have shown in this work is that introducing hydrogen can ensure those defects have less of an impact — which is known as passivation.

“Because hydrogen is modulating the defects within CZTS, that’s what helps increase its efficiency in terms of converting sunlight into electricity.”

Tandem solar

CZTS could be best implemented in what are known as tandem solar cells, which combine two or more solar cells to capture and convert more of the solar spectrum into electricity, improving overall efficiency.

Hao is hopeful that the new breakthrough will accelerate the chances of CZTS reaching 15% efficiency within the next year, and expects its commercialisation by 2030.

“There is still work to be done to find ways to further reduce the defects we find in CZTS, either during the fabrication or via post-fabrication treatments,” she said.

“But we know that this is a good material. When we consider the requirements from the bottom up, we know that we need something that is widely abundant, that is environmentally friendly, that has good optoelectronic properties and can last a long time — and CZTS fits the bill.”

Other tandem options

Hao and her team are also conducting research into another potential material that could partner with silicon: perovskite.

While perovskite is significantly more efficient (close to 27% in small-area examples) in converting the sun’s energy into electricity, it degrades quickly and contains highly toxic components that can dissolve in water, such as lead.

When considering perovskite, Hao said, “you can get really high performance and high efficiency at the beginning, but it’s much less stable and the panels might only last for one year, so it’s not sustainable”.

“It can take a long time to solve those problems, whereas with CZTS if we can get it to 20% efficiency then I think it will really take off because there are no other limitations since it meets all the criteria for the type of material we want to be using,” she added.

“Overall, I think we should be looking into all different types of materials for the top layer of tandem cells. That’s the only way we can maximise our chances of success and accelerate the speed towards obtaining highly efficient tandems that we can use long into the future.”

Top image caption: The UNSW research team with the record-breaking kesterite solar cell. Pictured are Dr Jialiang Huang, Dr Kaiwen Sun, Scientia Professor Xiaojing Hao and Ao Wang. Photo: UNSW Sydney.

0 Comments