by Komoneed | Aug 1, 2024

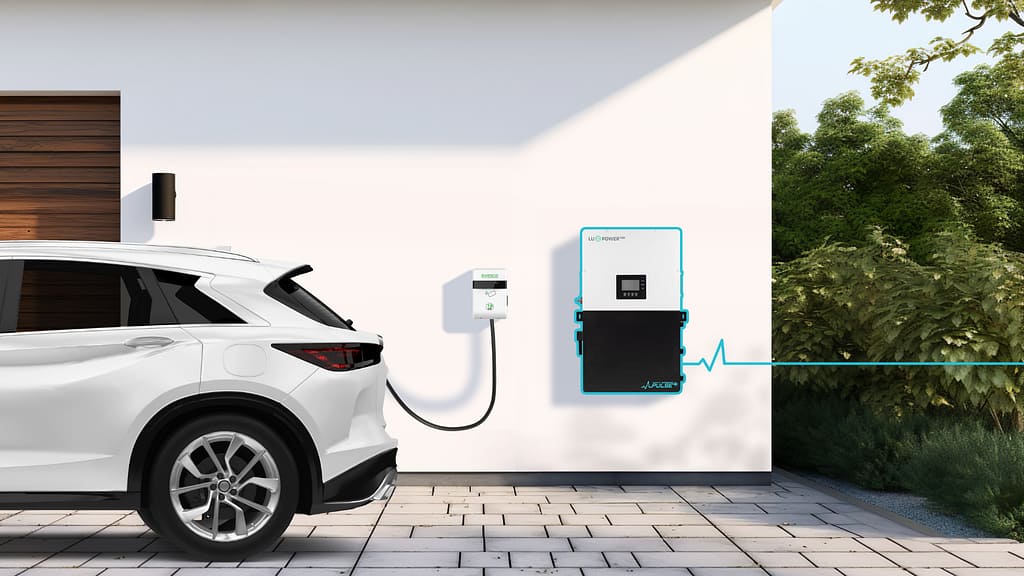

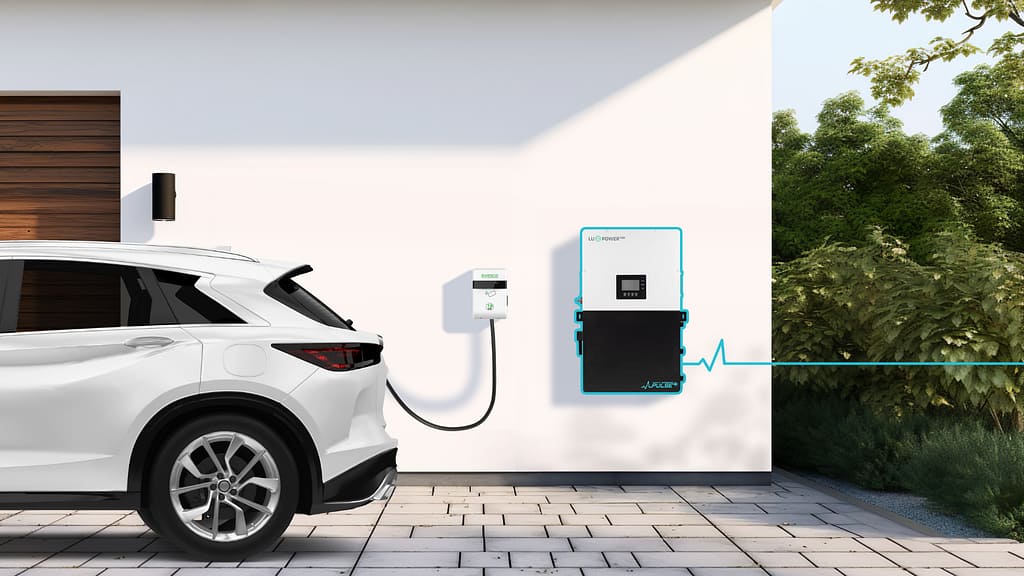

Welcome to the future of battery energy storage, with the Power Sonic Pulse. The Power Sonic Pulse series offers two unique battery energy storage models, allowing you to choose what to power. Whether you’re looking to power critical circuits, off-grid applications, or aiming to power your entire home, the Pulse series has a solution tailored … Continued

by Komoneed | Aug 1, 2024

A new report from Marine Conservation Society has determined an 80% decline in the amount of plastic bags found washed up on beaches in the past 10 years. The report links the decline in plastic bag waste to the enacting of fees for single-use plastic bags at large supermarket retailers in 2015. Marine Conservation Society […]

The post Plastic Bag Pollution on UK Beaches Falls 80% After Single-Use Bag Fee Policy, Report Finds appeared first on EcoWatch.

by Komoneed | Aug 1, 2024

Our editors curate highly rated brands that are first assessed by our rigorous ratings system. Buying through our links may earn us a commission—supporting the work we do. Learn more. Sunglasses are a year-round essential, but many of them are made from virgin plastic or animal-derived materials such as horn, so we’ve selected the […]

The post More Ethical and Sustainable Sunglasses That Leave Others In The Shade appeared first on Good On You.

by Komoneed | Aug 1, 2024

Mettler-Toledo Product Inspection reaffirms its ongoing commitment to environmental stewardship and a sustainable future by achieving carbon neutral status for the fifth consecutive year. Additionally, the company is on track to achieve its goal of sending zero waste to landfill by 2025.

In 2023, Mettler-Toledo has made substantial strides towards its sustainability objectives. Efforts include accelerating the adoption of electric vehicles, ramping up solar power and district heating capacities and re-achieving targets for sourcing 100% renewable electricity. These achievements reinforce the company’s commitment to sustainability and contribute to its 2030 science-based targets for emissions reduction.

The global business has also increased efforts related to sustainable product design, supplier engagement and transparency in its supply chain. The company’s direct supplier engagement program, initiated in 2022, has been further advanced, aligning with environmental, social and governance (ESG) goals and commitments. Leveraging risk assessments, the program targets suppliers where Mettler-Toledo can have the greatest impact, driving progress toward shared sustainability objectives.

For more information, visit here.

Image credit: iStock.com/Khanchit Khirisutchalual

by Komoneed | Aug 1, 2024

This post was originally published on UNDPThe Sea Isn’t the Only Thing Rising: Life, Death and Disease in the Pacific kate.smith@undp.org Wed, 07/31/2024 – 02:51 What can we do to address the complex interconnected threats of climate change? Multilateral...