by Komoneed | Nov 5, 2024

Our editors curate highly rated brands that are first assessed by our rigorous ratings system. Buying through our links may earn us a commission—supporting the work we do. Learn more. Shopping your values is hard enough, but if you have specific sizing or budget needs on top of that, it can seem particularly daunting. […]

The post 15 Size Inclusive and Affordable More Sustainable Brands You Need to Know appeared first on Good On You.

by Komoneed | Nov 5, 2024

The compact Suzuki e Vitara electric SUV will be available with four-wheel drive, and should arrive next summer

by Komoneed | Nov 5, 2024

This post was originally published on The Spin OffGoldwin 0 is Goldwin’s new platform focused on research, art...

by Komoneed | Nov 5, 2024

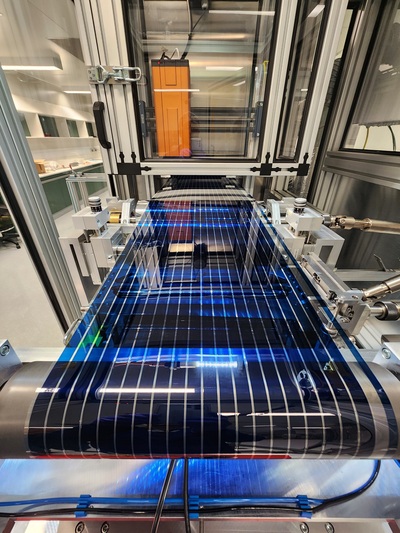

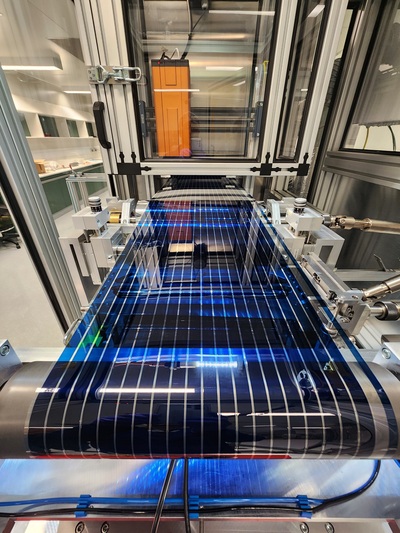

CSIRO has opened its $6.8 million facility in Clayton, Victoria, dedicated to taking its printed flexible solar technology out of the lab and into the real world to help meet the growing demand for renewable energy across sectors.

Unlike traditional silicon solar panels, CSIRO’s flexible solar cells are printed on thin plastic films. This makes them lightweight, portable and suitable for various applications across urban construction, space, defence, mining, emergency management, disaster relief and wearables.

The leader of CSIRO’s Renewable Energy Systems Group, Dr Anthony Chesman, said printed flexible solar is not intended to replace silicon rooftop panels, but rather to complement them.

“This printed solar technology unlocks entirely new applications for affordable, versatile and sustainable energy generation,” Chesman said.

Professor Elanor Huntington, CSIRO’s Executive Director, Digital, National Facilities and Collections, added: “Through CSIRO’s new Printed PV Facility, industry partners can access both researcher expertise and specialised equipment to improve and apply flexible solar technology in novel ways, anywhere there is sunlight.

“This not only offers incredible opportunities for Australian manufacturers but also contributes to addressing global energy challenges and advancing the transition to net zero.”

CSIRO’s solar cells are made using an advanced material called perovskite, which is printed on long continuous rolls of flexible film.

“Our new system is highly automated. The multiple printing and laminating steps are performed in a single continuous operation, which significantly cuts down on production costs and the upfront investment needed to get started,” Chesman said.

“Our team has also developed an automated system that can produce as many as 14,000 test solar cells a day to fine-tune their design and performance.

“We’re looking for partners who want to join us on the R&D journey and ultimately take this technology to market.

“Our industry partners will gain access to both our cutting-edge equipment and our team of world-class scientists with their deep expertise in solar technology.”

In addition to printed flexible solar, the lab is equipped to explore other fields that use printable materials for battery and hydrogen technologies, opening doors to a wider range of innovative applications.

Earlier this year, CSIRO set a new efficiency record for its flexible solar technology.

The Printed PV Facility received funding from Australian Renewable Energy Agency (ARENA) via the Australian Centre for Advanced Photovoltaics (ACAP).

by Komoneed | Nov 5, 2024

Orica has announced the completion of an environmental improvement project to reduce emissions of ammonium nitrate (AN) particulate from its Kooragang Island manufacturing site in the Hunter Valley.

The project has involved retrofitting the prill tower1 with an irrigated fibre-bed scrubber2 to capture particles of AN produced during the manufacturing process.

The abatement technology is designed to reduce AN particulate emissions, including fine particles with a diameter of 2.5 µm or less, by approximately 95%. The captured emissions are then recirculated in the manufacturing process to produce critical products for the resources and medical industries across Australia.

Orica President – Australia Pacific and Sustainability Germán Morales said the project is designed to ensure the sustainability of the Kooragang Island site.

“We understand and share the community’s desire for better air quality in general, and we are proud to play a role in achieving this,” Morales said.

“From start to finish, we have worked closely with the NSW Environment Protection Authority to ensure the project meets regulatory expectations and delivers optimal outcomes for the community and the environment.”

Designing, fabricating and installing the scrubber was a multi-year, large-scale and complex engineering project, with the construction phase alone taking more than 18 months or 115,000 work hours to complete.

“Retrofitting the scrubber to an existing and operating prill tower which stands at around 52 metres high has been technically challenging,” Morales said.

“Completing this project is a great achievement for the site and a real testament to the expertise of our people.”

1. The prill tower is where liquid ammonium nitrate is turned into small, solid ammonium nitrate balls (prill).

2. An irrigated fibre-bed scrubber is designed to clean the contaminants out of a gas stream. The first stage removes large particles via woven stainless steel mesh pads. The second stage removes fine particles via what are known as Brink filters. These filters are woven tubes that accumulate and coalesce the finer particulates into solution for collection in a sump at the bottom of the scrubber.