This post was originally published on Power Sonic

Global electric vehicle sales continue to be strong, with 4.3 million new Battery Electric Vehicles and Plug-in Hybrids delivered during the first half of 2022, an increase of 62% compared to the same period in 2021.

The growing number of electric vehicles on the road will lead to exciting changes to road travel and the EV charging infrastructure needed to support it. One of the more notable changes to the infrastructure we are seeing is the combination of EV charging equipment with battery energy storage systems.

The electrical network is far and wide. However, only some parts of the electrical grid are set up to support EV charging. With larger electric vehicle batteries and the growing demand for faster EV charging stations, access to more power is needed. There are 350kW + DC fast chargers, which could quickly draw more power than the electrical grid can supply in multiple locations. Fortunately, there is a solution, and that solution is battery energy storage.

The battery energy storage system can support the electrical grid by discharging from the battery when the demand for EV charging exceeds the capacity of the electricity network. It can then recharge during periods of low demand. Using battery energy storage avoids costly and time-consuming upgrades to grid infrastructure and supports the stability of the electrical network.

Using batteries to enable EV charging in locations like this is just one-way battery energy storage can add value to an EV charging station installation. Let’s look at the other benefits of using battery energy storage with electric vehicle charging stations.

REDUCE EV CHARGING COSTS

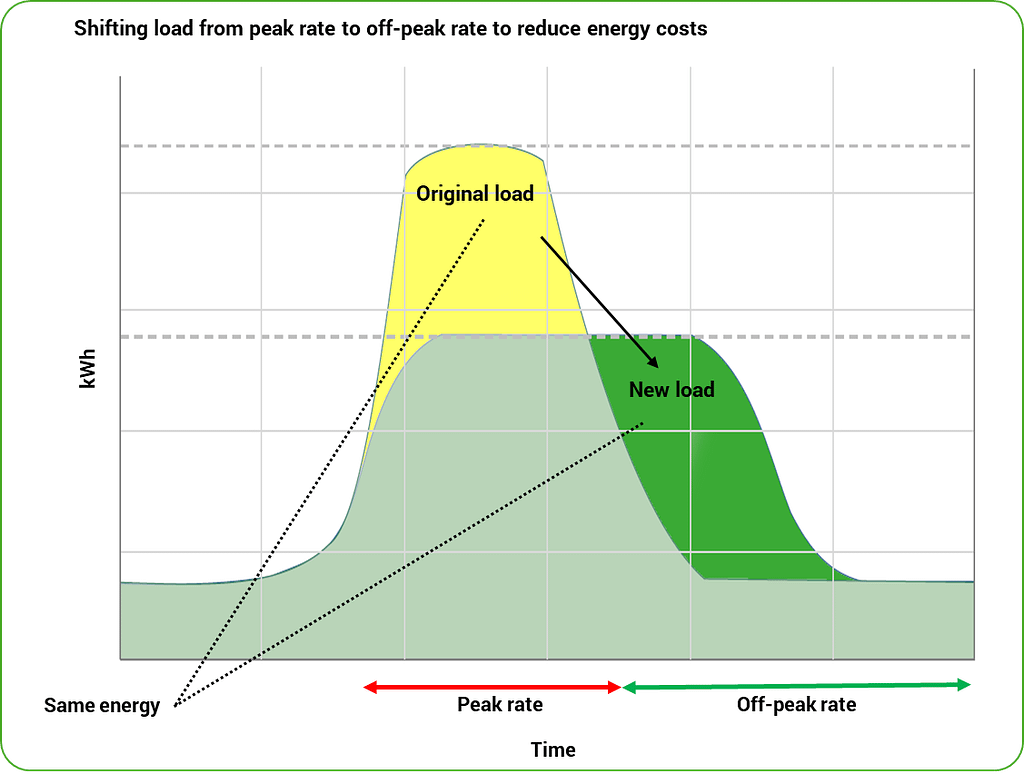

Battery energy storage can shift charging to times when electricity is cheaper or more abundant, which can help reduce the cost of the energy used for charging EVs. The battery is charged when electricity is most affordable and discharged at peak times when the price is usually higher. The energy consumption is the same in kWh. However, electricity use has shifted from an expensive peak rate to a less costly off-peak rate.

This gives a competitive advantage as you have paid less for your energy than nearby EV charging stations, meaning you can either be more competitive on pricing to attract more EV drivers or maximize profitability per charge.

As you can see below diagram, the same amount of energy consumption is shifted from the peak rate to the off-peak rate.

REDUCE DEMAND CHARGES

As well as being charged for your energy consumption in kWh from your utility company, more often than not, you will also be charged for your peak power usage in kW. This is the amount of power you draw from the electric grid in any 15-minute period. Battery energy storage systems can help reduce demand charges by storing electricity during low demand and releasing it when EV charging stations are in use. This can dramatically reduce the overall cost of charging EVs, especially when using DC fast charging stations. You effectively can ‘shave’ the peak demand, as illustrated in the diagram below. Discover more about lowering demand charges.

IMPROVE RELIABILITY AND RESILIENCE

Battery energy storage can provide backup power to charging stations during power outages or other disruptions, ensuring that EVs can be charged even when the grid is unavailable. This is especially important in emergency or evacuation situations; governments and municipalities must ensure that essential electric vehicle charging infrastructure can work during these events. The below diagram shows the difference between EV charging with battery energy storage and those without.

INCREASE EV CHARGING CAPACITY

Battery energy storage can increase the charging capacity of a charging station by storing excess electricity when demand is low and releasing it when demand is high. This can help to avoid overloading the grid and reduce the need for costly grid upgrades. In the example below, you will see that you can effectively increase the output power by adding battery energy storage. In this application sizing the battery energy storage system based on available grid power and EV charging demand is very important to ensure the battery can be charged in times of low demand.

INCREASE RENEWABLE ENERGY USE

Battery energy storage can store excess renewable energy generated by solar or wind and release it when needed to power EV charging stations. This can help increase renewable energy use and reduce reliance on fossil fuels. Using renewable energy sources and energy storage to power EV charging stations makes it possible to reduce greenhouse gas emissions and improve the overall sustainability of the transportation sector. Renewable energy, energy storage, EV charging, and clean energy generation are keys to reaching global Net-Zero targets.

ENHANCE GRID STABILITY

As mentioned earlier in this article, by storing excess electricity and releasing it when needed, battery energy storage can help smooth out fluctuations in demand and supply on the grid, improving overall grid stability and reliability.

IMPROVE EFFICIENCY

Battery energy storage systems can improve the overall efficiency of EV charging stations by reducing the amount of electricity lost during transmission and helping to optimize the charging process.

ENHANCE CONVENIENCE

With battery energy storage systems in place, EV charging stations can provide reliable, on-demand charging for electric vehicles, which is essential in locations where access to the electric grid is limited or unreliable. This can help to improve the overall convenience of EV charging for users and help enable EV charging anywhere.

Below is a video of an EVESCO battery energy storage system installed with DC fast charging stations.

Combing energy storage for EV charging has several benefits, as highlighted above, and as electric vehicle ownership grows, so will the demand for this type of infrastructure. We at EVESCO are excited about this innovative combination of technologies and are on hand to help you meet your EV charging needs.

0 Comments