This post was originally published on Eco Watch

Toxic chemicals from sewage sludge used as fertilizer pose health risks to those who regularly consume products from farms that use it, in some instances raising cancer risk by “several orders of magnitude” over what is considered acceptable by the United States Environmental Protection Agency (EPA), federal officials said on Tuesday.

EPA’s draft risk assessment, Draft Sewage Sludge Risk Assessment for Perfluorooctanoic Acid (PFOA) and Perfluorooctane Sulfonic Acid (PFOS), is a scientific evaluation of potential health risks to humans associated with toxic per- and polyfluoroalkyl substances (PFAS) “forever chemicals” in biosolids, or “sewage sludge,” a press release from EPA said.

“EPA under President Biden’s leadership has taken unprecedented actions to advance research and science on PFAS and to protect people from these dangerous forever chemicals,” said Jane Nishida, EPA’s acting administrator, in the press release. “This draft assessment provides important information to help inform future actions by federal and state agencies as well as steps that wastewater systems, farmers and other stakeholders can take to protect people from PFAS exposure, while ensuring American industry keeps feeding and fueling our nation.”

The findings show that exposure to PFOA or PFOS — two types of forever chemicals — during sewage sludge use and disposal methods may pose human health risks. The three methods are: surface disposal in landfills, land application of biosolids and incineration.

Once the assessment is finalized, it will assist EPA and partners in understanding the public health impacts posed by forever chemicals in biosolids, as well as inform potential future actions that could help reduce exposure risk.

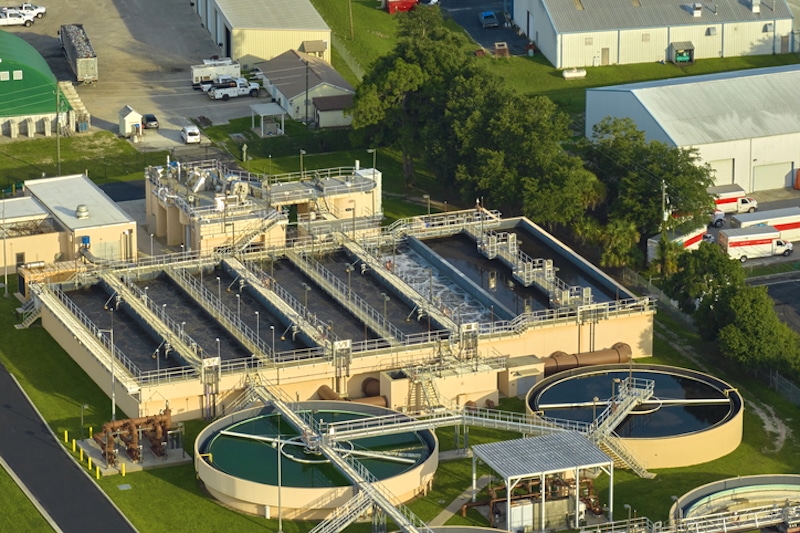

Wastewater gets conveyed to a treatment plant from businesses, households and industrial dischargers. The treatment processes produce a semi-solid product that is rich in nutrients called “biosolids” or “sewage sludge.”

“EPA typically uses the term ‘biosolids’ to mean sewage sludge that has been treated to meet regulatory standards and is thereby suitable to be land applied as a soil conditioner or fertilizer. In turn, biosolids can be beneficially reused as land applied fertilizer on agricultural fields or on nonagricultural lands to promote plant health and productivity,” EPA explained.

EPA’s draft risk assessment focused on a narrow and specific population that the agency considered most likely to have exposure to PFOS or PFOA from biosolids being applied to land or through the consumption of products produced on the land where biosolids were applied as fertilizer.

“The preliminary findings of the draft risk assessment indicate that there can be human health risks exceeding EPA’s acceptable thresholds, sometimes by several orders of magnitude, for some scenarios where the farmer applied biosolids containing 1 part per billion (ppb) of PFOA or PFOS (which is near the current detection limit for these PFAS in biosolids),” the press release said.

The risk assessment used scientific modeling of hypothetical health risks to humans who live on or near sites that have been impacted by PFOS or PFOA or for those who mostly rely on products from the sites, such as animal products, food crops or drinking water.

“EPA risk assessments follow a scientific process to characterize the nature and magnitude of health risks to children, adults, and the environment from pollutants based on modeled exposure scenarios. An environmental risk assessment considers three primary factors: 1) presence (i.e., how much of a pollutant is present in the environment); 2) exposure (i.e., how much contact a human or wildlife has with the pollutant); and 3) the toxicity of the pollutant (i.e., the health effects the pollutant causes in humans or wildlife),” EPA said.

The modeled scenarios included farms that used one application of 10 dry-metric-tons per hectare of the biosolids for 40 consecutive years.

The modeling also found human health risks above the EPA acceptable standards in scenarios where 1 part per billion of PFOS or PFOA was put in a clay-lined or unlined surface disposal unit.

Once the draft risk assessment is finalized, EPA will use it to “help inform future risk management actions for PFOA and PFOS in sewage sludge. For the incineration scenario, risk is not quantified due to significant data gaps,” the press release said.

The analysis did not suggest that the country’s general food supply was contaminated by biosolids containing PFOS or PFOA, but the U.S. Department of Agriculture and the Food and Drug Administration are conducting broad PFAS monitoring in the food supply and have taken actions to address products that have been impacted from imported and domestic sources.

According to the “best available data,” biosolids make up less than a percent of fertilized acreage of the nation’s productive agricultural lands annually. There are specific “hot spots” recognized by EPA, and certain farming operations could have higher PFOS or PFOA levels if they used contaminated sludge.

EPA said “further collaboration with impacted operations and other federal agencies will be important to fully understand risks and support impacted farmers.”

The analysis found that PFOS and PFOA risks of exposure from biosolids increased proportionally with how much of the chemicals were present.

“This means that if you lower the concentration of PFOA or PFOS in biosolids or the amount of biosolids applied to agricultural land, you lower the risk. The actual risks from exposure to PFOA or PFOS will vary at farms that land-apply biosolids or at biosolids disposal sites based on the amount of PFOA or PFOS applied, as well as geography, climate, soil conditions, the types of crops grown and their nutrient needs and other factors.,” EPA said.

The draft risk assessment’s findings highlight the importance of proactive state and federal policies to remove and control PFAS at their source.

“Moving forward, EPA is working to set technology-based limits on discharges from several industrial categories — including PFAS manufacturers, electro- and chrome-platers and landfills — under the agency’s Effluent Limitations Guidelines program,” the press release said. “Several states have begun monitoring for PFAS in sewage sludge and published reports and data that are publicly available.”

The post PFAS ‘Forever Chemicals’ Used on Farms Could Significantly Raise Health Risks, EPA Draft Guidelines Warn appeared first on EcoWatch.

0 Comments