This post was originally published on Eco Watch

A research team from the Graz University of Technology (TU Graz) in Austria and India’s Vellore Institute of Technology (VIT) have been working on the development of 3D-printed imitations of human skin that could potentially be used to replace animals in cosmetics testing.

Directive 2010/63/EU, European legislation “on the protection of animals used for scientific purposes,” laid out restrictions for testing cosmetics and their ingredients on animals in the European Union that have been in effect since 2013.

Since then, scientists have been looking for alternatives for testing the toxicity and absorption of cosmetics such as suntan lotion.

“The hydrogels for our skin imitation from the 3D printer have to fulfill a number of requirements,” said Professor Karin Stana Kleinschek, a researcher with the Institute of Chemistry and Technology of Biobased Systems, in a press release from TU Graz. “The hydrogels must be able to interact with living skin cells. These cells not only have to survive, but also have to be able to grow and multiply.”

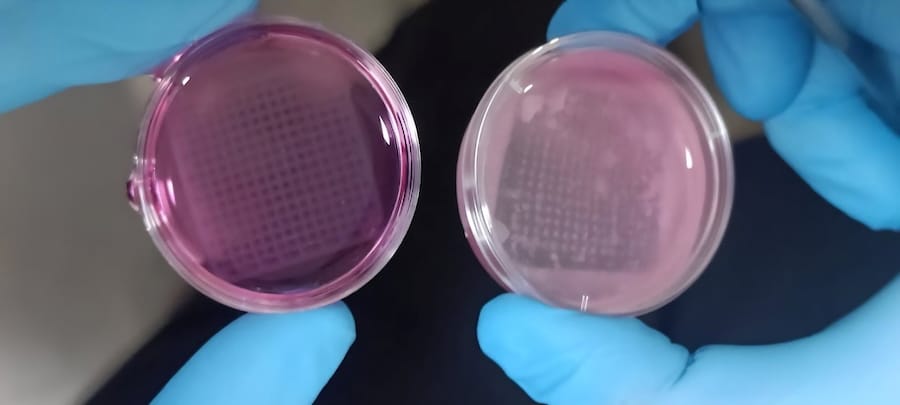

3D-printed structure with human keratinocytes. Manisha Sonthalia / Vellore Institute of Technology

The team is working to develop skin imitations that mimic human skin’s natural biomechanics and three-layer tissue structure. The imitations are made up of hydrogel formulations that can be printed along with living cells.

Hydrogels have a high-water content, which provide the ideal conditions for the growth and integration of cells. But the high-water content also means the 3D prints must be mechanically and chemically stabilized.

“TU Graz is working intensively on cross-linking methods for stabilization. Ideally, following nature’s example, the cross-linking takes place under very mild conditions and without the use of cytotoxic chemicals,” the press release said.

Once the prints have been stabilized, the researchers in India test the toxicity and resistance of the 3D prints. Before imitation skin would be able to be developed, however, skin cells from the hydrogel would have to be able to survive for two or three weeks in cell culture before a skin imitation would be able to be produced. The imitation skin could then be used in cell tests on cosmetics.

The first 3D-printed hydrogels tested in cell culture were successful.

“In the next step, the 3D-printed models (skin imitations) will be used to test nanoparticles,” Kleinschek said. “This is a success for the complementary research at TU Graz and VIT. Our many years of expertise in the field of material research for tissue imitations and VIT‘s expertise in molecular and cell biology have complemented each other perfectly. We are now working together to further optimize the hydrogel formulations and validate their usefulness as a substitute for animal experiments.”

The findings of the study, “Protocol for the fabrication of self-standing (nano)cellulose-based 3D scaffolds for tissue engineering,” were published in the journal STAR Protocols.

The post Could a 3D-Printed Skin Imitation Replace Animal Testing for Cosmetics? appeared first on EcoWatch.

0 Comments