This post was originally published on Eco Watch

Earth Overshoot Day is the point in the year when human demand for materials obtained from nature exceeds what the Earth can naturally regenerate in one year. For 2025, Earth Overshoot Day fell on July 24, the earliest it has been since the event was first calculated in 2006.

The Earth Overshoot Day was first launched in 2006 by Andrew Simms, an author, political economist and campaigner, in collaboration with Global Footprint Network, as reported by Sustainability Magazine. Since then, Earth Overshoot Day is calculated and announced annually. Since 2006, the date has come earlier and earlier, signaling just how rapidly human consumption habits are growing and stripping the planet of its resources.

This year, Global Footprint Network also recalculated previous Earth Overshoot Days, even prior to 2006, for greater accuracy.

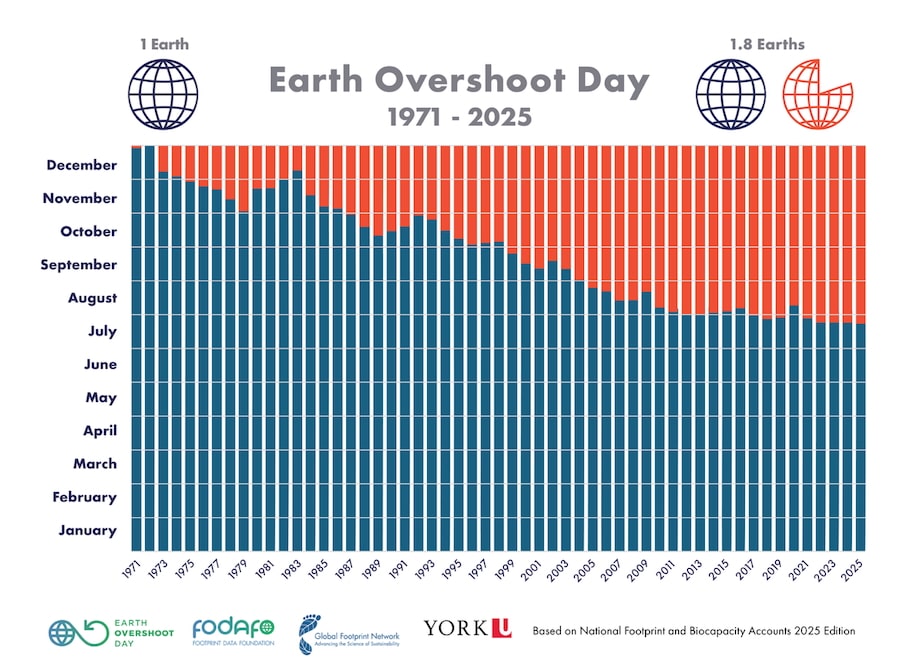

According to the latest calculations, Earth Overshoot Day fell as late as December 31 in 1972 but crept up to November 3 by 1979. In the early 1980s, the date went back into early December, only to reach October 12 by 1989.

The date stayed in October from 1989 until 1999, when it reached September 25. In 2006, when Earth Overshoot Day was first announced, the latest calculations put the event on August 22.

The date reached July for the first time in 2018, returned back to August briefly in 2020, and has remained in July ever since. The previous earliest record was July 25, which happened in 2022 and 2023. The world reaching its earliest-ever Earth Overshoot Day highlights how much humanity is consuming and how nature cannot continue to keep up with such high demand.

Today is #EarthOvershootDay.

Falling on July 24th means that humanity is currently using nature 1.8 times faster than Earths ecosystems can regenerate.

#OvershootDay— Global Footprint Network (@footprintnetwork.bsky.social) July 24, 2025 at 12:33 AM

We are currently using nature 1.8 times faster than it can regenerate, according to Global Footprint Network. Consumption of freshwater, trees, and seafood are all examples of natural items that cannot replenish as quickly as they are depleted, not to mention that humanity is emitting far more carbon than ecosystems can absorb.

But as Global Footprint Network pointed out in this year’s Earth Overshoot Day announcement, depleting resources at this pace has a cumulative effect, even if the date stays steady. With consumption outpacing replenishment, the pressure increases, as we have already seen with humanity nearly exceeding seven of nine planetary boundaries.

“We are stretching the limits of how much ecological damage we can get away with. It is now a quarter into the 21st century and we owe the planet at least 22 years of ecological regeneration, even if we stop any further damage now,” Lewis Akenji, board member of Global Footprint Network, said in a statement. “If we still want to call this planet home, this level of overshoot calls for a scale of ambition in adaptation and mitigation that should dwarf any previous historical investments we have made, for the sake of our common future.”

It is not too late to start correcting course for the future. According to Global Footprint Network, moving the date is possible through several different actions that have been outlined in a campaign called the Power of Possibility.

One of the biggest improvements would be by cutting carbon emissions 50% to move Earth Overshoot Date farther into the year by three months.

Reducing global food waste by half would push the date 13 days, establishing a Green New Deal at global scale could move the date 42 days, and generating at least 75% of electricity from renewables could push the date by 26 days.

“Because of the nature of physics, overshoot cannot last. It will end either by deliberate design or dumped-on disaster,” Mathis Wackernagel, co-founder and board member of Global Footprint Network, said in a statement. “It should not be too hard to choose which one is preferable, particularly in light of so many possible choices.”

The post Earth Overshoot Day Reaches Record for Earliest Date appeared first on EcoWatch.

0 Comments