This post was originally published on Sustainability Times

Source: Sustainability Times

| IN A NUTSHELL |

|

In a remarkable fusion of technology and nature, scientists have made groundbreaking strides by developing an energy harvester the size of a grain of rice. This tiny device can attach to bees, harnessing their natural wing vibrations to generate electricity. This innovation not only highlights the potential of bio-inspired designs but also underscores the importance of sustainable energy sources. As we delve deeper into this fascinating development, we explore how these minute devices are set to transform insect cyborgs into efficient power generators without hindering their natural abilities.

Bee-Inspired Energy Harvesters: A Tiny Marvel

The quest for efficient energy solutions has led researchers to explore unconventional avenues, and the creation of a piezoelectric energy harvester (PEH) is a testament to this innovation. By aligning the harvester’s resonant frequency with the bees’ natural thorax vibrations, scientists achieved a remarkable energy output without compromising the bees’ flight capabilities. Weighing in at an astonishingly light 46 milligrams, this device exemplifies how engineering can mimic biological systems to achieve efficiency and sustainability.

Constructed from flexible PVDF films, the harvester utilizes a double-crystal design to enhance voltage output. By precisely tuning it to the bees’ thoracic vibration frequency of 210–220 Hz, energy conversion becomes efficient, while the absence of bulky batteries extends the operational lifespan of the insect cyborgs. This innovation not only showcases the power of biomimicry but also sets a new standard for energy harvesting systems that do not interfere with the natural behavior of living organisms.

Revolutionizing Renewable Energy with Bee Power

The development of this tiny energy harvester marks a significant advancement in renewable energy technologies. By utilizing the natural wing vibrations of bees, scientists have managed to create a system that can generate electricity without external power sources. This approach not only provides a sustainable energy solution but also highlights the potential of nature-inspired designs in modern engineering.

Using advanced techniques like laser-cutting and 3D-printed molds, the researchers crafted an ultralight device that seamlessly integrates into the bees’ natural environment. This design ensures minimal disruption to the bees’ flight, allowing them to hover, flip, and fly with ease. As the world grapples with energy challenges, innovations like these offer a glimpse into a future where renewable energy solutions are derived from the natural world.

The Science Behind the Buzz: How It Works

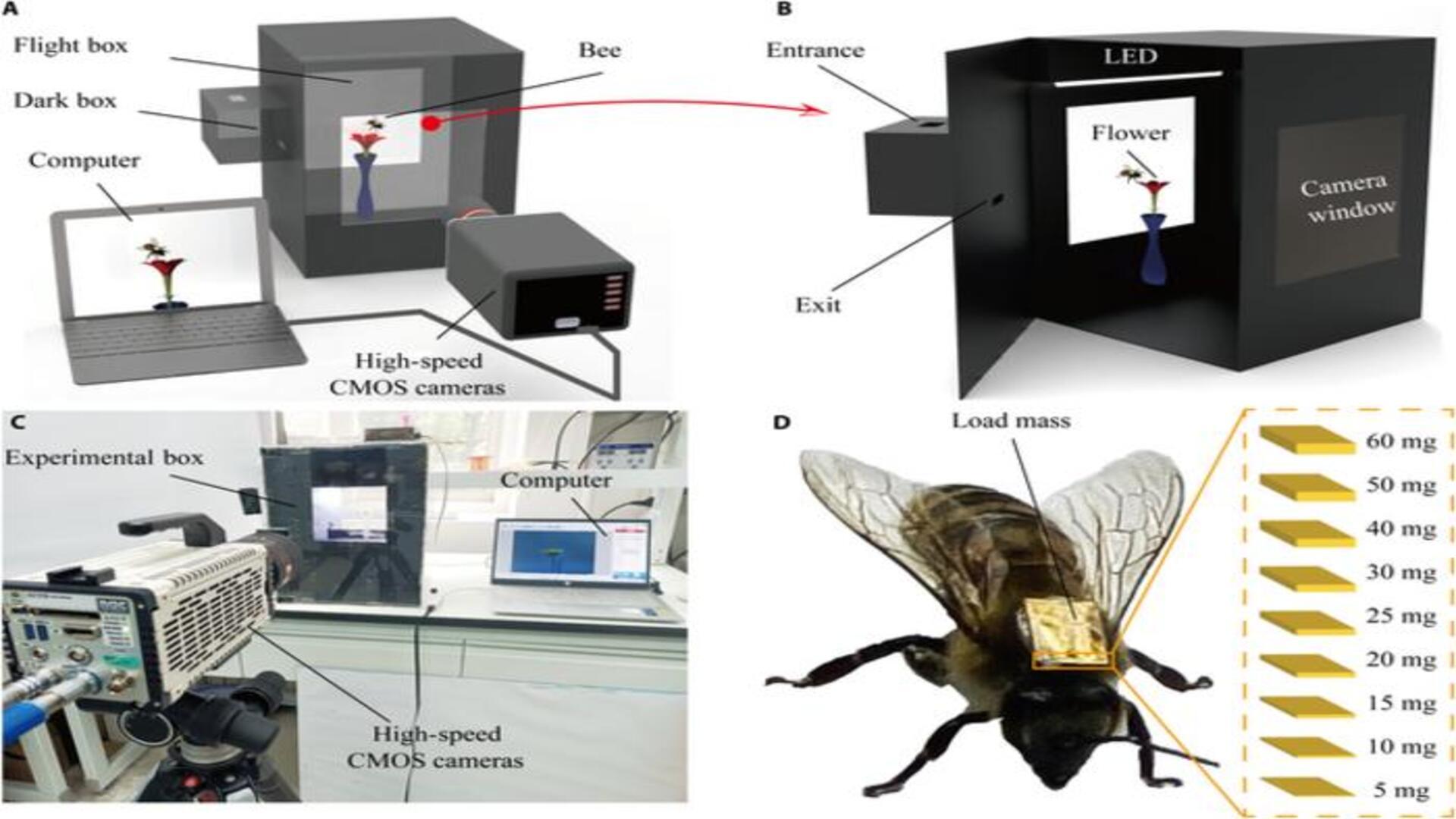

At the heart of this innovation is meticulous scientific research and development. The team employed multiphysics simulations using Comsol to accurately predict the device’s performance. By analyzing wing-flapping dynamics with high-speed CMOS cameras, they optimized the harvester’s resonance frequency, ensuring it operates efficiently under varying conditions.

Despite its small size, the harvester produces an impressive energy output of 5.66 volts and a power density of 1.27 milliwatts per cubic centimeter. This efficient energy conversion is achieved by integrating frequency interval matching with center-of-gravity optimization, allowing for stable flight without biomechanical disruptions. However, challenges such as energy storage and scalability remain, paving the way for further research and development in this field.

Future Prospects: Expanding the Horizon

The successful deployment of these energy harvesters on bees is just the beginning. Researchers are already looking to expand this methodology to other insects like dragonflies and butterflies, aiming to establish standardized energy solutions for biohybrid systems. This innovation opens new possibilities for self-sustaining insect cyborgs, potentially revolutionizing fields such as environmental monitoring and rescue missions.

As researchers focus on integrating energy management circuits and expanding scalability, the potential applications of this technology seem limitless. By relying on physics-driven optimization rather than trial and error, the development process becomes more streamlined and efficient. This breakthrough serves as a beacon for future technological advancements, heralding a new era of sustainable energy solutions inspired by nature.

This remarkable fusion of biology and technology underscores the limitless potential of renewable energy solutions inspired by nature. As we continue to explore the applications of these tiny energy harvesters, one can’t help but wonder: what other secrets does nature hold that could transform our approach to sustainable energy?

The post Bees Turned into Buzzing Powerhouses: Tiny Rice-Sized Tech Transforms These Pollinators into Renewable Energy Generators, Revolutionizing Sustainability appeared first on Sustainability Times.

Scientists have developed a rice-sized energy harvester that attaches to bees, generating electricity from their wing vibrations.

Scientists have developed a rice-sized energy harvester that attaches to bees, generating electricity from their wing vibrations. The device leverages piezoelectric technology, using flexible PVDF films to achieve efficient energy conversion without disturbing bee flight.

The device leverages piezoelectric technology, using flexible PVDF films to achieve efficient energy conversion without disturbing bee flight. By integrating frequency interval matching and center-of-gravity optimization, the harvester produces an energy output of 5.66 volts.

By integrating frequency interval matching and center-of-gravity optimization, the harvester produces an energy output of 5.66 volts. Researchers aim to expand this methodology to other insects, paving the way for self-sustaining insect cyborgs in environmental monitoring and rescue missions.

Researchers aim to expand this methodology to other insects, paving the way for self-sustaining insect cyborgs in environmental monitoring and rescue missions.

0 Comments